1. Introduction

On December 11, 2025, 2:00 PM EST, xLM will host a LinkedIn Live session demonstrating how Continuous Temperature Mapping (cTM) is transforming environmental monitoring in pharmaceutical manufacturing, biotech operations, warehousing, and cold-chain environments.

This newsletter expands on our earlier article, adding more insights, clarity, and real-world examples.

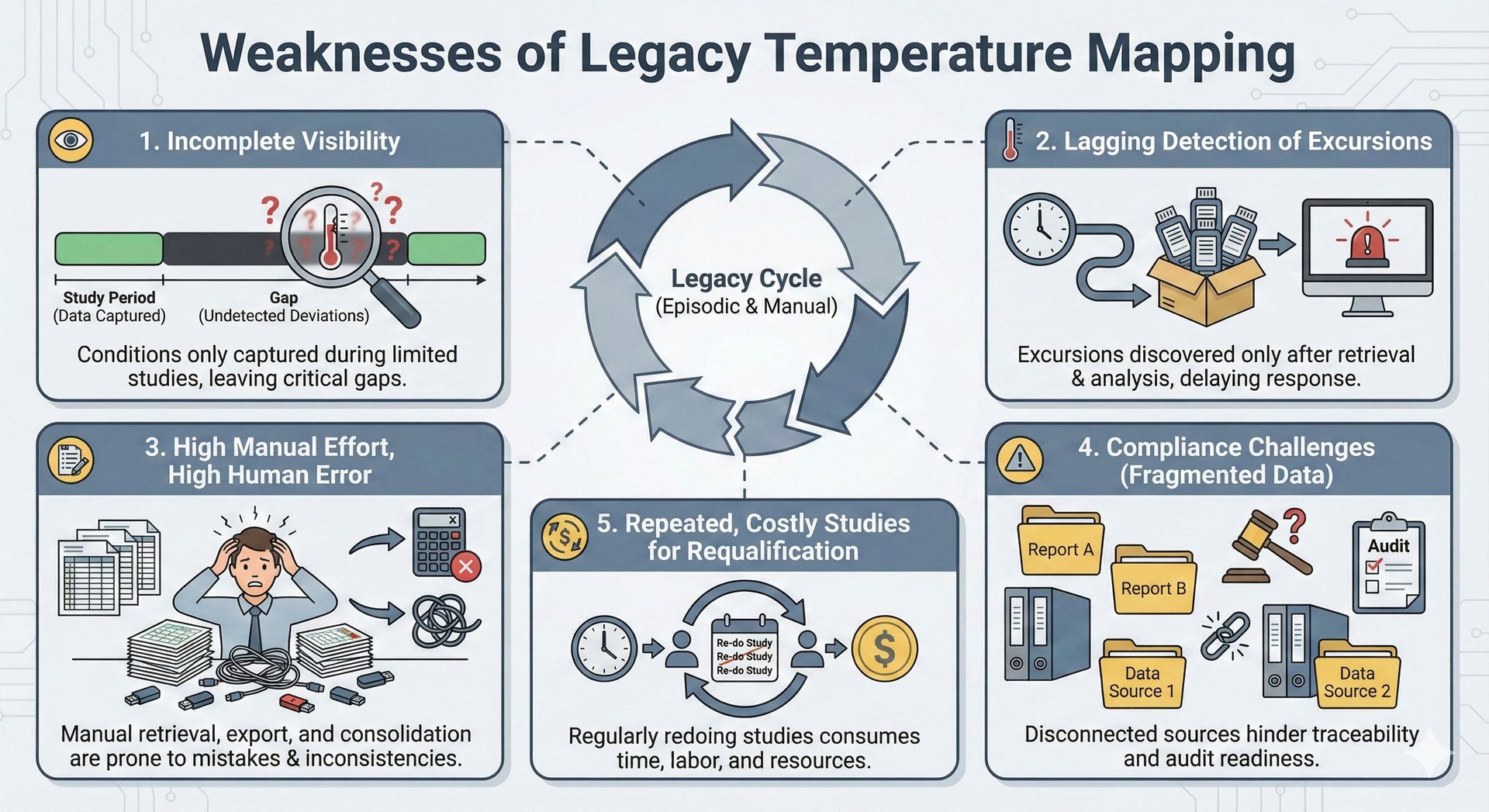

2. Why legacy temperature mapping can’t keep up anymore

Traditional temperature mapping studies are episodic, you deploy data loggers for a validation cycle, retrieve them days later, export data manually, analyze spreadsheets, and generate static reports. This results in:

Incomplete visibility (data only during studies): Environmental conditions are captured only during limited study periods, leaving gaps where critical deviations may go undetected.

Lagging detection of excursions: Temperature or humidity excursions are discovered only after data retrieval, delaying response and risking product integrity.

High manual effort, high human error: Teams spend hours retrieving loggers, exporting files, and consolidating spreadsheets, a manual workflow prone to mistakes and inconsistencies.

Compliance challenges due to fragmented data: Disconnected data sources and static reports hinder traceability, audit readiness, and data integrity.

Repeated, costly studies for requalification: Facilities regularly redo mapping studies to maintain compliance, consuming time, labor, and resources.

Modern GxP operations require continuous assurance, traceability, and audit readiness that old processes cannot provide.

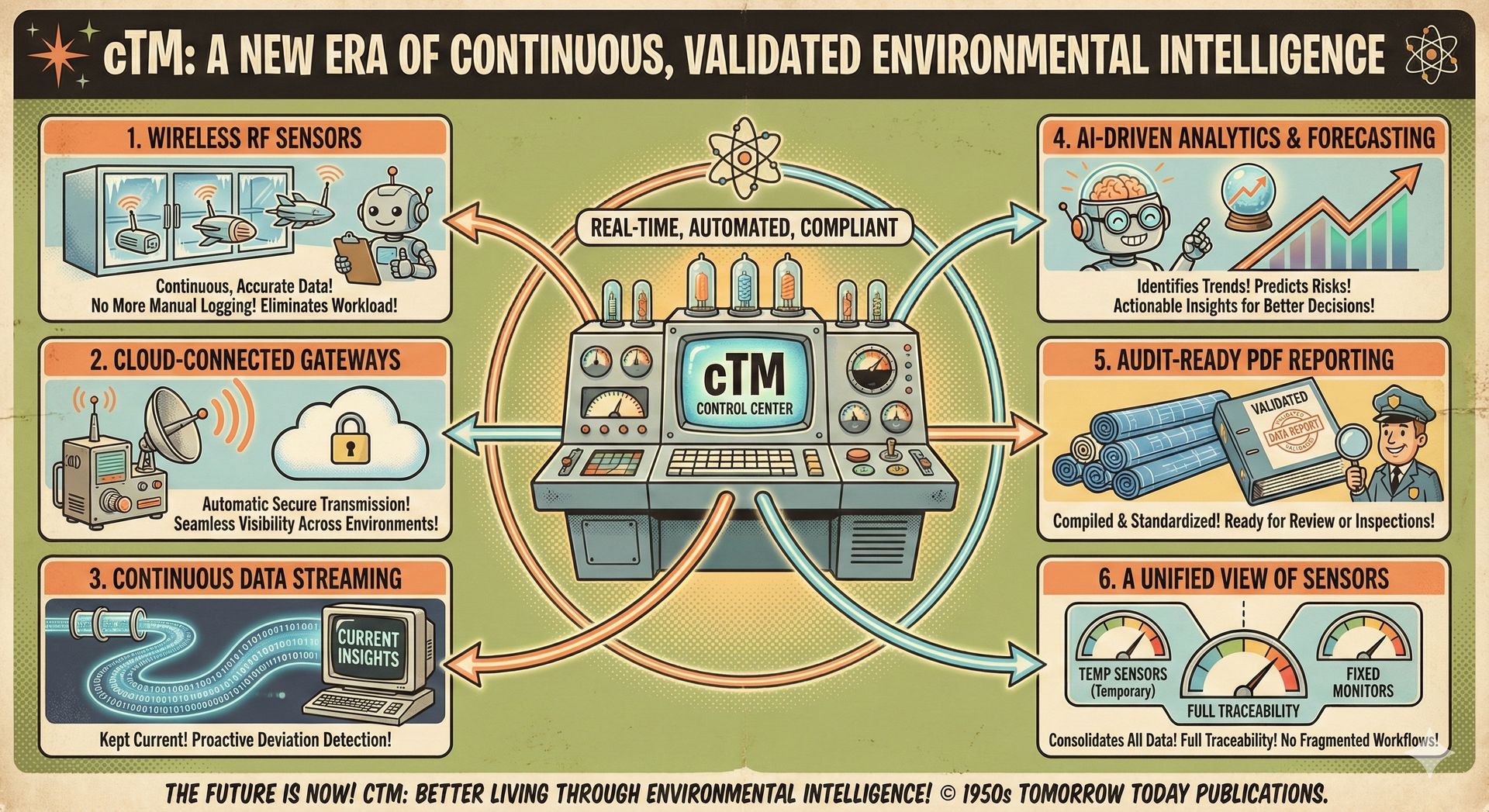

3. cTM: A new era of continuous, validated environmental intelligence

cTM transforms temperature mapping into a real-time, automated, compliant digital workflow by integrating:

Wireless RF sensors – These sensors capture temperature data continuously with high accuracy, eliminating manual logger handling and reducing validation workload.

Cloud-connected gateways – Gateways collect sensor data automatically and securely transmit it to the platform, ensuring seamless, real-time visibility across environments.

Continuous data streaming – Streaming keeps temperature insights current, enabling proactive deviation detection instead of waiting for post-study analysis.

AI-driven analytics & forecasting – AI identifies trends, predicts risks, and provides actionable insights to improve compliance and operational decisions.

Audit-ready PDF reporting – Reports compile validated data, annotations, and compliance narratives into standardized formats ready for review or inspections.

A unified view of temporary + fixed sensors – This view consolidates all mapping and monitoring data into one dashboard, ensuring full traceability and eliminating fragmented workflows.

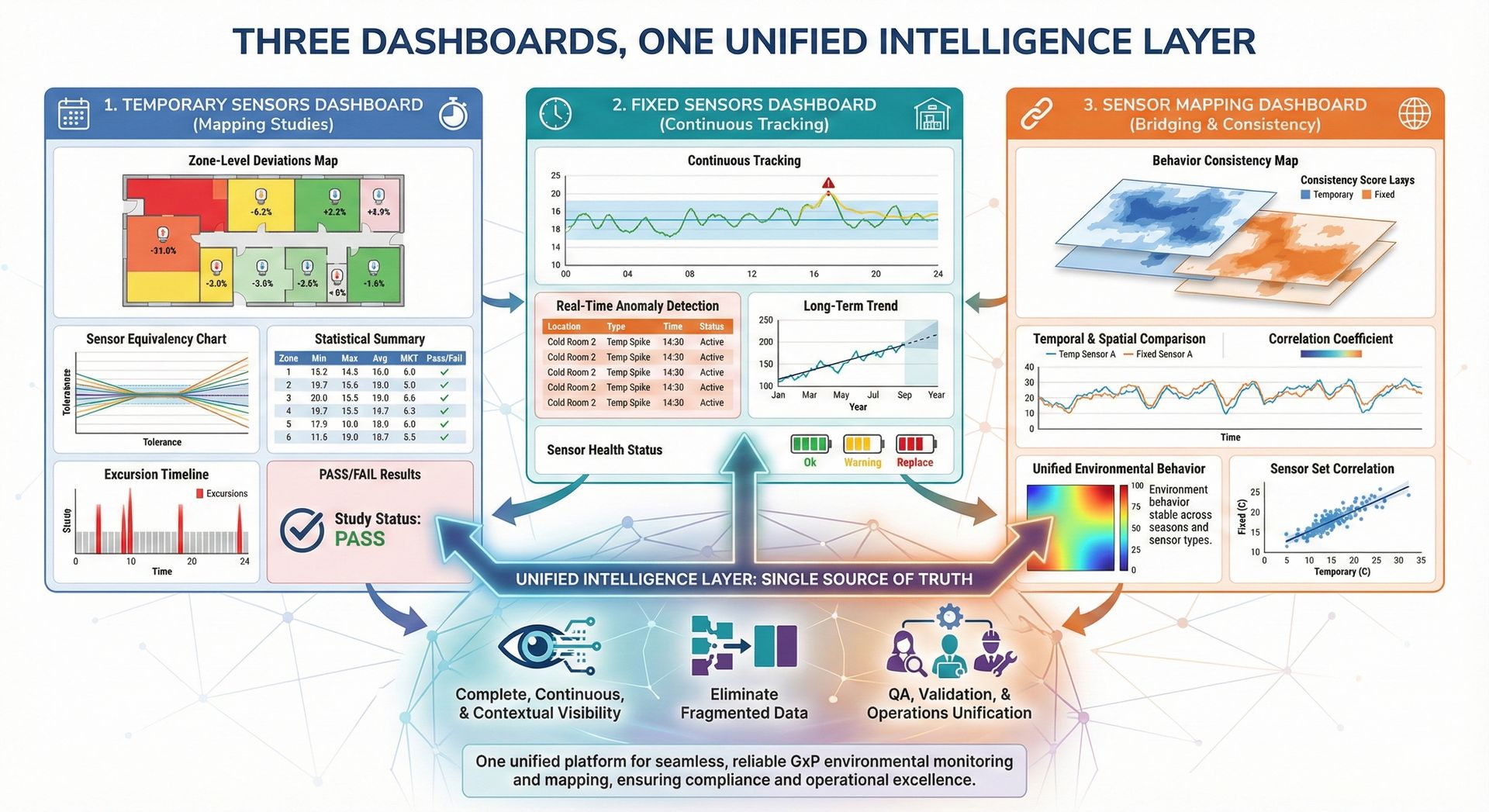

4. Three dashboards, one unified intelligence layer

Modern GxP environments require complete, continuous, and contextual visibility. cTM delivers this through three dashboards that unify all environmental data, providing QA, validation, and operations teams a single, reliable source of truth across temporary studies, fixed monitoring, and long-term environmental behavior.

1. Temporary Sensors Dashboard

Used in mapping studies, it shows zone-level deviations, sensor equivalency, statistical summaries, excursion timelines, and pass/fail results.

2. Fixed Sensors Dashboard

Ideal for warehouses, cold-rooms, and clean-rooms, it provides continuous tracking, anomaly detection, long-term trends, and sensor health.

3. Sensor Mapping Dashboard

Bridges temporary and fixed sensors, showing whether the environment behaves consistently over time and across sensor sets.

Together, they eliminate fragmented data and give QA, validation, and operations team a single source of environmental truth.

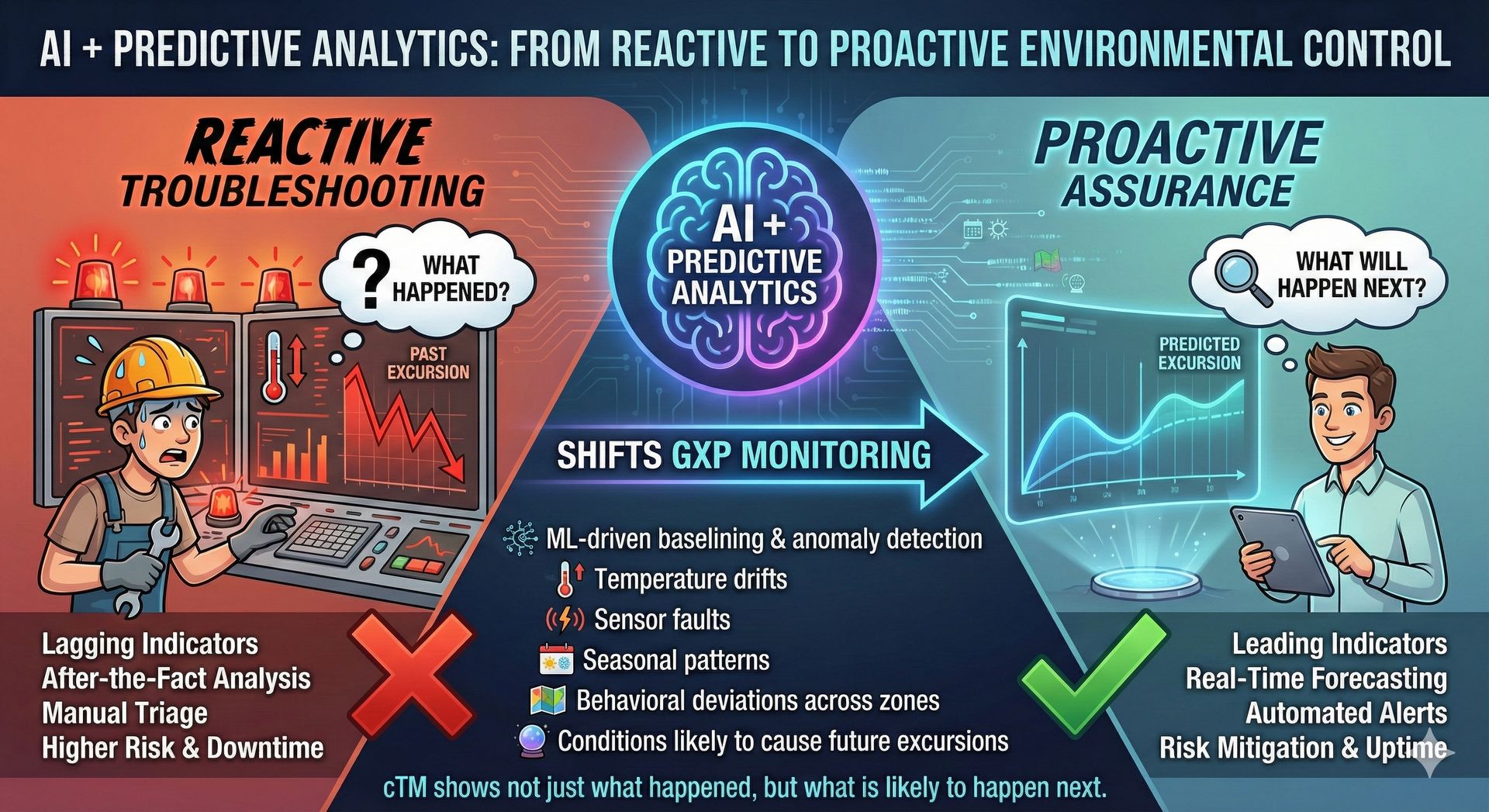

5. AI + predictive analytics: from reactive to proactive environmental control

cTM doesn’t just tell you what happened, it shows what is likely to happen next.

With ML-driven baselining and anomaly detection, the system detects:

Temperature drifts

Sensor faults

Seasonal patterns

Behavioral deviations across zones

Conditions likely to cause future excursions

This shifts GxP environmental monitoring from reactive troubleshooting to proactive assurance.

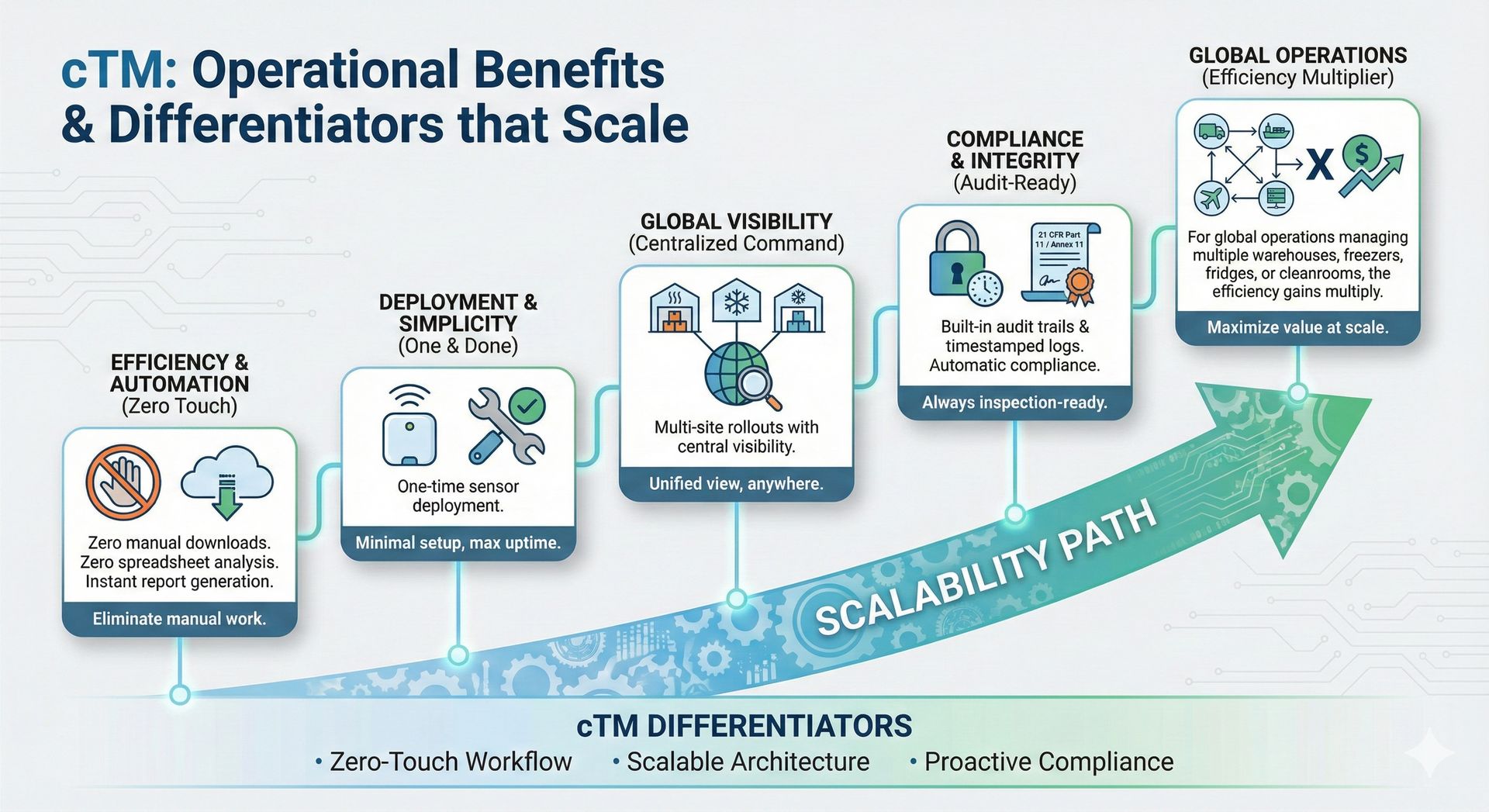

6. Operational benefits that scale with you

cTM delivers measurable value across the organization:

Zero manual downloads

Zero spreadsheet analysis

Instant report generation

One-time sensor deployment

Multi-site rollouts with central visibility

Built-in audit trails & timestamped logs

Automatic compliance with 21 CFR Part 11 & Annex 11

For global operations managing multiple warehouses, freezers, fridges, or cleanrooms, the efficiency gains multiply.

7. Join the LinkedIn live demo — see cTM in action

The 30-minute session includes:

Live walkthrough of dashboards

Real-time data streaming demonstration

Review of mapping study workflows

Automated PDF reporting showcase

Compliance deep dive

Q&A with experts

📅 December 11, 2025 🕒 2:00 PM EST

This is the fastest way to see how cTM can modernize your environmental monitoring program.