Table of Contents

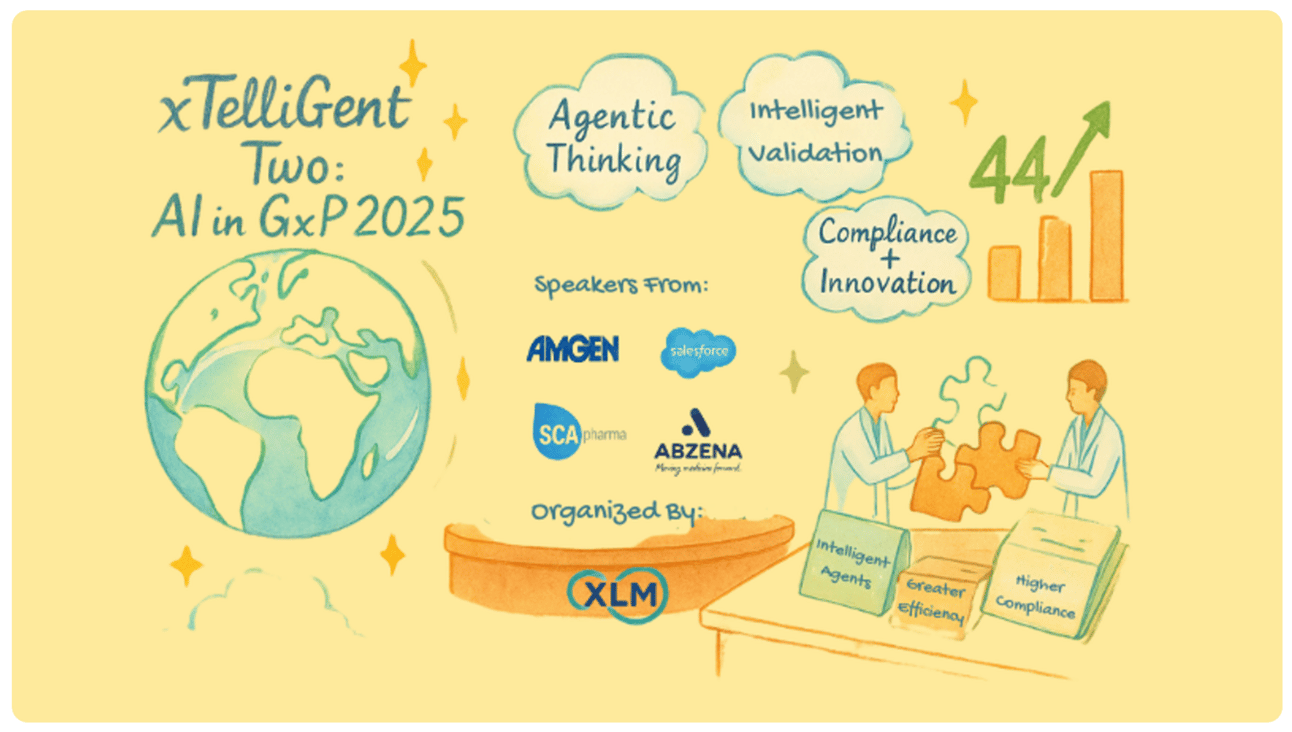

The pharmaceutical industry witnessed a pivotal moment on May 28, 2025, as the xTelliGent Two: AI in GxP Summit brought together over 100 industry leaders from 14+ countries to explore the revolutionary convergence of artificial intelligence and GxP compliance. This virtual summit showcased groundbreaking technologies that are fundamentally reshaping how pharmaceutical organizations approach manufacturing, validation, and regulatory compliance, delivering tangible results that industry pioneers are already implementing in production environments.

1.0 Keynote Excellence: Charting the Future of Agentic AI in Life Sciences

The summit opened with a transformative keynote presentation delivered by two industry luminaries: Himanshu Jain, Technology Strategy and Innovation Leader at Amgen, and Ashwin Kumar, CTO of xLM. Their presentation illuminated four critical dimensions where Agentic AI is revolutionizing regulated life sciences environments, setting the strategic foundation for the entire summit experience.

The keynote emphasized how AI has evolved from passive analytical tools to active collaborators in scientific workflows, representing a fundamental paradigm shift for life sciences organizations. These advanced autonomous systems demonstrate sophisticated contextual reasoning capabilities, executing complex experimental protocols independently while engaging human expertise only when confronted with anomalies or critical decision points. This evolution addresses one of the pharmaceutical industry's most pressing challenges: maintaining rigorous scientific standards while dramatically accelerating research and development timelines.

Particularly compelling was the discussion of regulatory excellence through intelligent automation, where Agentic AI serves as a strategic asset for maintaining compliance within highly-regulated environments. The technology creates more robust frameworks for quality assurance by continuously monitoring parameters, predicting potential compliance issues, and maintaining comprehensive documentation trails across the validation continuum. This capability directly addresses the industry's need for enhanced regulatory confidence while reducing the administrative burden that often constrains innovation.

The keynote also highlighted accelerated return on technology investment, identifying specific applications within bioprocessing, quality control, and manufacturing workflows where Agentic AI systems deliver exponential productivity improvements. These targeted implementations offer rapid deployment opportunities with substantial operational benefits, particularly in areas requiring repetitive verification or complex data interpretation—challenges that pharmaceutical organizations face daily.

2.0 Revolutionary Intelligent Validation: From Days to Minutes

One of the summit's most electrifying demonstrations showcased xLM's autonomous AI agents performing end-to-end validation processes that traditionally consume days of manual effort, compressed into mere minutes of autonomous execution. Presented by Shyam Patadia and Nagesh Nama from xLM, this live demonstration revealed how intelligent agents, trained explicitly in GxP protocols and governed by rock-solid compliance frameworks, can revolutionize validation workflows.

The demonstration highlighted autonomous authoring of User Requirements Specifications (URS) documents with unprecedented precision and consistency, eliminating the variability and time constraints associated with manual documentation processes. These AI agents seamlessly generate test cases directly from URS requirements without manual input, ensuring comprehensive coverage while maintaining traceability standards that exceed traditional validation approaches.

Most remarkably, the agents execute validation protocols in real-time with complete traceability, building comprehensive trace matrices that ensure full test coverage against all requirements. The system delivers GxP-compliant documentation ready for audit and submission, addressing one of the pharmaceutical industry's most resource-intensive challenges. This capability represents a quantum leap in validation efficiency, transforming what was previously a bottleneck into a competitive advantage.

The implications for pharmaceutical organizations are profound. By automating validation processes while maintaining rigorous compliance standards, companies can accelerate product development timelines, reduce resource allocation to routine validation tasks, and focus human expertise on higher-value scientific activities. This technological advancement directly addresses the industry's perpetual challenge of balancing speed-to-market pressures with regulatory requirements.

3.0 Agentic Process Automation: Transforming Manufacturing Intelligence

The summit extensively explored how agentic process automation is revolutionizing pharmaceutical manufacturing through intelligent, autonomous systems that process raw Industrial Internet of Things (IIoT) data into valuable, real-time insights while maintaining GxP compliance. These capabilities build upon the foundation established at the previous xTelliGent One summit, demonstrating the rapid evolution of AI applications in regulated environments.

The demonstrations revealed how autonomous agents rapidly transform disparate data streams into actionable intelligence, featuring intelligent continuous validation, predictive analytics, and sophisticated data visualization capabilities. Traditional legacy processes were directly compared with these cutting-edge agents, showcasing dramatic time savings where hours of work are compressed into minutes of automated processing. This efficiency gain represents more than mere automation—it fundamentally changes how pharmaceutical organizations can respond to manufacturing challenges and opportunities.

Particularly impressive was the integration of conversational AI capabilities that empower users to directly interact with their data, gaining unprecedented insights with intuitive ease. This development democratizes data analysis within pharmaceutical organizations, enabling scientific and manufacturing teams to extract meaningful insights without requiring specialized data science expertise. The implications for decision-making speed and accuracy are transformative, particularly in manufacturing environments where rapid response to process variations can determine product quality and regulatory compliance.

The summit also highlighted successful implementations where AI predicts system degradations and implements corrective actions in real-time, significantly enhancing operational efficiency while minimizing manual interventions. This predictive capability represents a strategic advantage for pharmaceutical manufacturers, enabling proactive rather than reactive approaches to quality management and process optimization.

4.0 Intelligent Temperature Mapping: Revolutionizing Environmental Monitoring

A standout session presented by Tanay Agrawal and Nagesh Nama from xLM demonstrated how intelligent temperature mapping and environmental monitoring systems are eliminating traditional pain points associated with tedious setup, manual data logging, costly errors, and lengthy audits. This presentation showcased xLM's Intelligent Mapping Platform as a comprehensive solution that automates the entire mapping lifecycle using advanced agents, AI-powered validation, and real-time data interaction capabilities.

The live demonstration revealed a streamlined six-step process that transforms environmental monitoring from a regulatory burden into a strategic advantage. The process begins with simple sensor placement requiring no complex setup or IT overhead, followed by automatic data flow to GxP-validated cloud infrastructure within minutes. Real-time visualization capabilities enable continuous monitoring and interaction with live data as studies progress, while voice-activated query capabilities allow users to literally speak with their data for immediate insights.

The system's ability to upload and instantly analyze fixed Building Management System (BMS) sensor data post-study represents a significant advancement in data integration capabilities. Automated GxP reports, intelligent key performance indicators, alerts, and visual dashboards are delivered instantaneously, addressing one of the pharmaceutical industry's most time-consuming compliance requirements. This automation eliminates audit anxiety by providing comprehensive, immediately available documentation that exceeds regulatory expectations.

The scalability demonstrations showed how these autonomous agents handle data collection, analysis, and reporting without human intervention while scaling effortlessly to thousands of sensors and millions of records. For pharmaceutical organizations managing multiple facilities and complex environmental monitoring requirements, this capability represents both significant cost savings and enhanced compliance confidence.

5.0 Industry Impact and Strategic Foundations for AI Implementation

Michael Stannius Aagren from UniBio provided crucial insights into laying the foundation for successful AI implementation, emphasizing that while AI holds transformative potential, many initiatives falter due to misalignment, unrealistic expectations, and inadequate planning. His presentation offered a practical roadmap for organizations seeking to implement AI sustainably and effectively in high-stakes pharmaceutical environments.

The session emphasized strategic preparation principles, recognizing that AI enhances human decision-making rather than replacing it entirely. Success begins with well-defined goals, robust business cases, and realistic scope definition—foundational elements that many pharmaceutical organizations overlook in their enthusiasm for AI adoption. This guidance provides essential guardrails for responsible AI implementation in regulated environments.

Leadership and alignment emerged as critical success factors, requiring executive commitment, appropriate budgeting, and appointment of AI ambassadors to foster internal engagement from the ground up. The pharmaceutical industry's hierarchical nature and risk-averse culture make these leadership elements particularly crucial for successful AI initiatives. Without proper organizational alignment, even technically superior AI solutions may fail to achieve adoption and impact.

Data and infrastructure readiness received particular emphasis, highlighting the need for clean, consistent, and well-governed data supported by secure and scalable infrastructure. Pharmaceutical organizations often struggle with data silos, legacy systems, and inconsistent data quality—challenges that must be addressed before AI implementation can succeed. The session provided practical guidance for establishing these foundational elements.

6.0 Looking Forward: Why xTelliGent Three is Essential

The remarkable success of xTelliGent Two, evidenced by its 100+ attendees from 14+ countries and 20+ sessions featuring live demonstrations and real-world case studies, establishes this summit series as the premier forum for AI advancement in pharmaceutical manufacturing. The live demonstrations of autonomous validation, intelligent temperature mapping, and agentic process automation showcased technologies that are not merely conceptual but actively transforming pharmaceutical operations today.

The upcoming xTelliGent Three summit in November represents an unmissable opportunity for pharmaceutical organizations to stay at the forefront of AI-driven transformation. Given the rapid pace of technological advancement demonstrated at xTelliGent Two, the November summit will likely showcase even more sophisticated applications and real-world implementations that early adopters have developed since May. Organizations that miss this opportunity risk falling behind competitors who are actively leveraging these transformative technologies.

The pharmaceutical industry stands at an inflection point where AI technologies are transitioning from experimental implementations to production-ready solutions delivering measurable business value. The technologies demonstrated at xTelliGent Two—autonomous validation, intelligent environmental monitoring, and agentic process automation—represent competitive advantages that forward-thinking organizations are already implementing. The November summit will provide essential insights into scaling these implementations and discovering new applications that can drive operational excellence.

7.0 Conclusion

xTelliGent Two: AI in GxP Summit 2025 demonstrated that the convergence of artificial intelligence and pharmaceutical manufacturing is not a future possibility but a present reality delivering tangible results today. From autonomous validation systems that compress days of work into minutes, to intelligent temperature mapping platforms that eliminate audit anxiety, to agentic process automation that transforms manufacturing intelligence, the technologies showcased represent fundamental shifts in how pharmaceutical organizations can operate.

The summit's success, measured by its international participation, industry-leading speakers from organizations like Amgen, xLM, Abzena, and Salesforce, and live demonstrations of production-ready technologies, establishes it as the definitive forum for AI advancement in regulated environments. The insights shared by industry pioneers provide both strategic vision and practical implementation guidance for organizations seeking to harness AI's transformative potential while maintaining rigorous compliance standards.